Quality is the very definition of an authentic Fitzgerald's piece. We feel it is part of our responsibility to educate our clients and our colleagues on the significant differences in furniture design and creation. From creating one of a kind patterns, to the hand stitching of chair skirts, J.F. Fitzgerald craftsmanship is reliably superior.

Below find a gallery illustrating some of these differences in the way other companies build furniture and the way J.F. Fitzgerald's has been producing quality furniture from the very beginning.

Below find a gallery illustrating some of these differences in the way other companies build furniture and the way J.F. Fitzgerald's has been producing quality furniture from the very beginning.

8-Way Hand Tie vs. No-Sagged Construction

These seats will not sit the same.

Coil springs for chair and sofa seats are hand tied and adjusted to the customer’s exact specifications.

8-way hand tie (pics on left) will sit comfortably for a lifetime while a no-sagged construction (pic on right) will not sit as comfortably.

While customers think they can remedy a poor construction with a new fill on their cushions, in reality, the couch has lost its spring.

Coil springs for chair and sofa seats are hand tied and adjusted to the customer’s exact specifications.

8-way hand tie (pics on left) will sit comfortably for a lifetime while a no-sagged construction (pic on right) will not sit as comfortably.

While customers think they can remedy a poor construction with a new fill on their cushions, in reality, the couch has lost its spring.

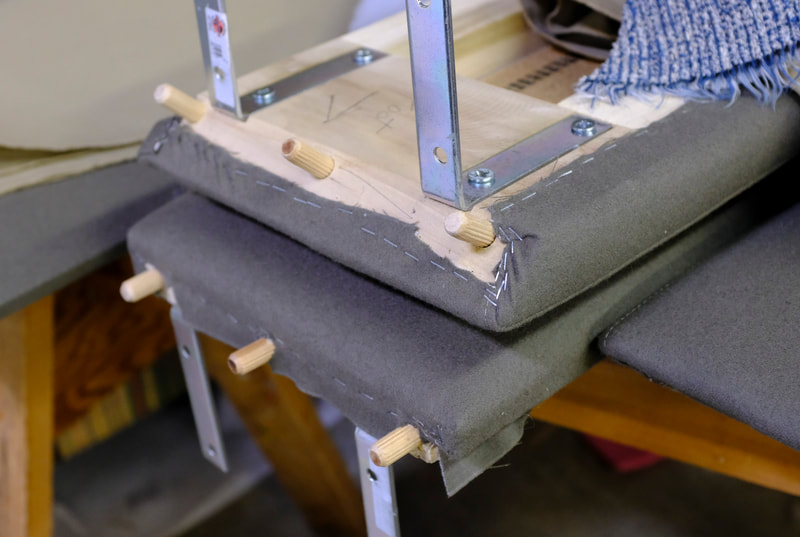

Natural Wood vs. Compressed Wood and Plywood

Lower quality materials and poor construction means that pieces may break more easily under weight.

At J.F. Fitzgerald's, we use natural wood and reinforce the joints with double dowels and gussets to be sure it will last a lifetime.

At our on-site mill, we cut the wood extra thick for a sturdier frame deserving of our Lifetime Frame Guarantee.

At J.F. Fitzgerald's, we use natural wood and reinforce the joints with double dowels and gussets to be sure it will last a lifetime.

At our on-site mill, we cut the wood extra thick for a sturdier frame deserving of our Lifetime Frame Guarantee.

Cushions

We make every cushion by hand for our custom orders—a time consuming specialty you’ll seldom find elsewhere.

Made To Order

While most of our designs are standard, each piece is still made to customer specifications.

If you want firm foam, we can do that.

If you want down, we can do that..

If you want specific depths or lengths, we can do that too.

Unlike catalogs and showrooms, where selections are oftentimes limited, custom design is our strength and hallmark.

For half a century, we’ve understood that quality resides in the client catered details of craftsmanship.

If you want firm foam, we can do that.

If you want down, we can do that..

If you want specific depths or lengths, we can do that too.

Unlike catalogs and showrooms, where selections are oftentimes limited, custom design is our strength and hallmark.

For half a century, we’ve understood that quality resides in the client catered details of craftsmanship.

429 Cabot Road, South San Francisco, CA 94080

p 415.648.6161

f 415.648.6162

p 415.648.6161

f 415.648.6162

© COPYRIGHT 2020

ALL RIGHTS RESERVED.

ALL RIGHTS RESERVED.

Website Design, Spotted Dog Graphics